(HYGRO)TEMP'O

Presentation

The (HYGRO)TEMP'O sensor is a LoRaWAN class A sensor that uses a disposable 3.6V AA-type battery as power supply. It also includes an internal antenna.

It measures the temperature, the relative humidity. It is possible to get the voltage of the power supply. An alert is sent when the device is moved after association.

| Accuracy tolerance | |

|---|---|

| Temperature (°C) | +/- 0.2 |

| Humidity (%) | +/- 2 |

Family code

The family code of HYGROTEMP'O devices is: 50-70-205-xxx / 50-70-232-xxx [tropicalized and soldered battery]

The family code of TEMP'O devices is: 50-70-231-xxx

For other family code 50-70-162/191 and 50-70-167 please read support

For other family code 50-70-053 and 50-70-085 please read support

LoRaWAN release

v1.0.2 Region Parameter rev B

User guide

Notice Utilisateur FR 50-70-[205_231-232]

Installation and operation

Installation

The housing is intended to be installed inside a building.

First, fix the lid of the sensor to the wall using screws or double-side tape. Then attach the case that contains the electronic board to the lid.

It is important to start the device once fixed to the wall. The tilt box's pull-out alert function is based on the angle with the vertical. This initial angle is taken at startup, and a periodic check of the angle is performed. If the angle varies by more than 4 degrees from the initial position, then the alert is triggered. It is necessary to return to the initial angle ±2 degrees for the alert to be deactivated.

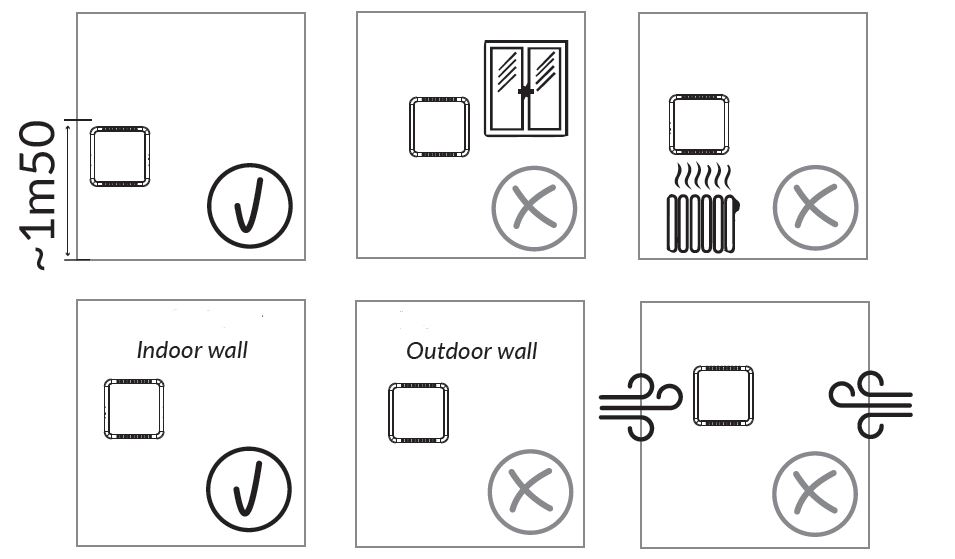

Radio propagation

In order for the sensor to operate correctly, the number of obstacles should be limited in order to avoid excessive radio wave attenuation. It is also important to place the sensor as high as possible, not in contact with outside. The device should be placed away from windows, heat input (sun, radiator, ventilation, air intake,...)

Autonomy

The information in the table below represents how long the battery can last. It is based on the default configuration at ambient temperature (+25°C) within the optimal operating range of the sensor via a LoRaWAN network (one uplink frame), when the spreading factor used is SF12.

The disposable battery has a 2.6Ah capacity, of which 85% is used.

| Transmission and Measure periodicity | Spreading Factor | Battery life |

|---|---|---|

| 12 hours / 1 hour | 12 | 10 years |

| 2 hours / 30 min | 12 | 10 years |

| 1 hour / 10 min | 12 | 7 years |

| 1 hour / 10 min | 9 | 10 |

Human Machine Interface

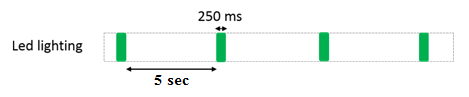

There are two LEDs on the device:

Green: blinking until the association with a network is done. Since release v3.5.2.5530, after 6 hours in association searching the led blinks all 1 minute.

Red: blinking in configuration mode.

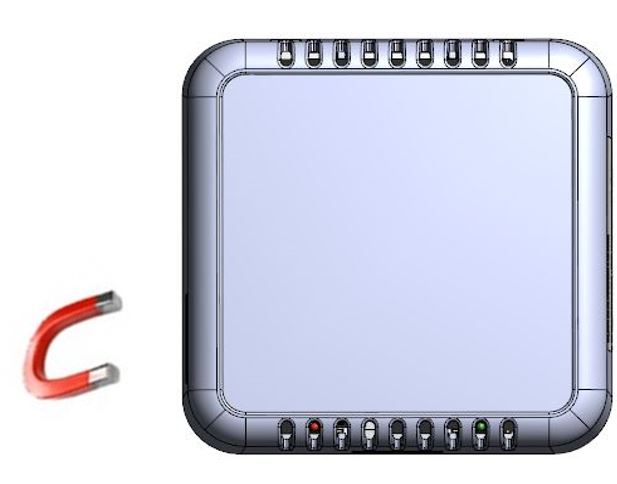

A magnet can be used to activate it and perform specific actions on the sensor (switch off, switch on, reassociation…). When the reed switch is activated, the red LED blinks quickly.

To start up the device, a magnet must be placed next to the sensor for one second to the configuration sticker (the "gears"). The red LED blinks quickly during this step. After one second, the red LED stops blinking and the green LED blinks slowly until the association is done.

To switch off the device, repeat the same operation by placing the magnet next to the sensor for 5 seconds. After those 5 seconds, the red LED blinks 5 times slowly.

- Configuration

| Way to trigger it | One passage of the magnet near the reed switch or specific ZCL command |

| Way to stop it | Another passage of the magnet or specific ZCL command |

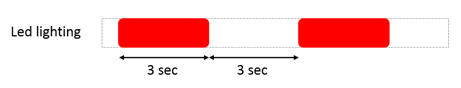

| Effects on the sensor | The CONF led (red) blinks (3 sec. OFF, 3 sec. ON) and the sensor sends an uplink frame every minute. |

| Duration | The configuration mode lasts 10 minutes |

- A reassociation procedure can be requested if no downlink frame is received by the sensor during a given periodicity (4 days by default) or if a given number (100 by default) is reached or in case of failure (no acknowledgement received) by sending an applicative frame to the sensor or via the sensor’s IHM.

The sensor keeps the AppEUI and DevEUI configured, Confirmed/Unconfirmed configuration and all applicative configurations. However, LoRaWAN configurations (channel, data rate …) are lost.

| Way to trigger it | Three passages of the magnet near the reed switch or ZCL command from LoRaWAN cluster. |

| Effects on the sensor | The ASSN led (green) blinks as the “no commissioned sensor” LED is lit. |

- A factory reset is available on Watteco’s sensors. It deletes all the applicative settings saved in the flash memory (i.e. configured batches and reports will be deleted).

The sensor keeps the AppEUi and DevAddr configured. However, LoRaWAN configurations (channel, data rate…) and applicative configurations are lost.

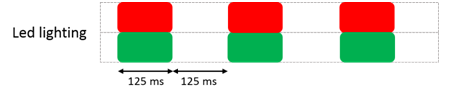

| Way to trigger it | Two quick passages and a long passage of the magnet near the reed switch |

| Effects on the sensor | The CONF LED (red) and ASSN LED (green) blink at the same time briefly. All the applicative settings (for batches and reports) are deleted. The blinking is illustrated below this table. |

Applicative layer

Codecs are available to decode frames: Downloads

The (HYGRO)TEMP'O device integrates the following clusters:

| Cluster | Cluster name | Managed attributes |

|---|---|---|

| 0x0000 | Basic | All |

| 0x0050 | Configuration | All Threshold is available |

| 0x8004 | LoRaWAN | All |

| 0x0402 | Temperature Measurement | All Threshold is available |

| 0x0405 | Relative Humidity Measurements | All Threshold is available |

| 0x000F | Binary Input | All |

The binary input is available and connect to the opening of the casing.

Default configuration

A default configuration is set:

- The device reports a "batch" of temperature / humidity from every 1 hour with a measure all 10 minutes.

The configuration of batch is :

| Features | Label (size= 2) | Measure periodicity | Transmission periodicity | resolution |

| Temperature | 0 | 10 minutes | 1 hour | 0.1°C |

| Relative Humidity | 1 | 10 minutes | 1 hour | 1% |

| Battery Voltage | 2 | 7 days | 7 days | 1mV |

Every change made to the default configuration must comply with the legal duty cycle (for example, the most restrictive in the EU is 0.1%, which corresponds to approximately 1 frame per hour with SF12)

To decode the default "batch" is necessary to use this argument: 2 0,10,7 1,100,6 2,1,6 3,1,1 .

Measurement periodicity

The measurement periodicity depends on the minimum and maximum, and the delta fields.

If the value of the minimum and the delta is 0, then the maximum value is the periodicity of measurement.

However, if the value of delta is different than 0, then the periodicity of measurement is the configured delay of the min field.

In batch mode, if delta = 0 then the measurement is done and recorded all mininmum field delay.

Frame examples

All frames have to be sent on port 125

Report

Report of a batch → Applicative payload is: 220000C081938297B457C0140108D009645E1968B707 {

"batch_counter": 0,

"batch_relative_timestamp": 3670,

"batch_absolute_timestamp": "2020-11-19T09:34:13.289",

"dataset": [

{

"data_relative_timestamp": 1870,

"data": {

"value": 2654,

"label": 0,

"label_name": "Temperature"

},

"data_absolute_timestamp": "2020-11-19T09:04:13.289Z"

},

{

"data_relative_timestamp": 3670,

"data": {

"value": 2434.0,

"label": 0,

"label_name": "Temperature"

},

"data_absolute_timestamp": "2020-11-19T09:34:13.289Z"

},

{

"data_relative_timestamp": 1870,

"data": {

"value": 2712,

"label": 1,

"label_name": "RelativeHumidity"

},

"data_absolute_timestamp": "2020-11-19T09:04:13.289Z"

},

{

"data_relative_timestamp": 3670,

"data": {

"value": -34588.0,

"label": 1,

"label_name": "RelativeHumidity"

},

"data_absolute_timestamp": "2020-11-19T09:34:13.289Z"

}

]

}

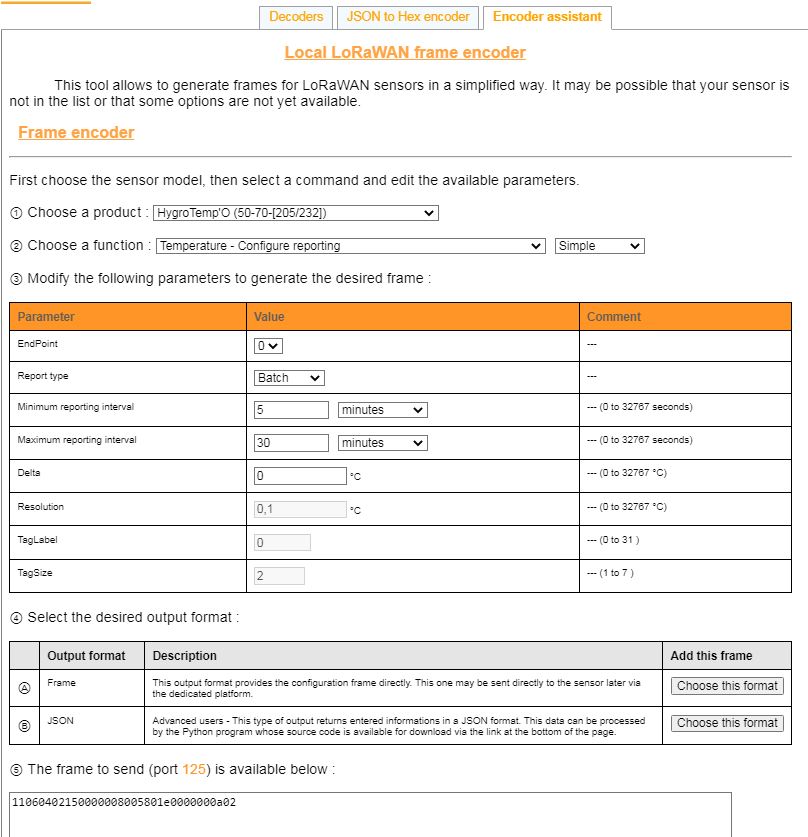

Configuration

Modify report on the temperature Modify the periodicity of measure to 5 minutes and sending all 30 minutes of temperature. The frame is : 11060402150000008005803c0000000a02 →Response from the device: 11 07 04 02 00 00 00 00 To disable the previous configuration, change the value of the minimum and maximum sending intervals and the delta to 0