PT1000 temperature sensor

Presentation

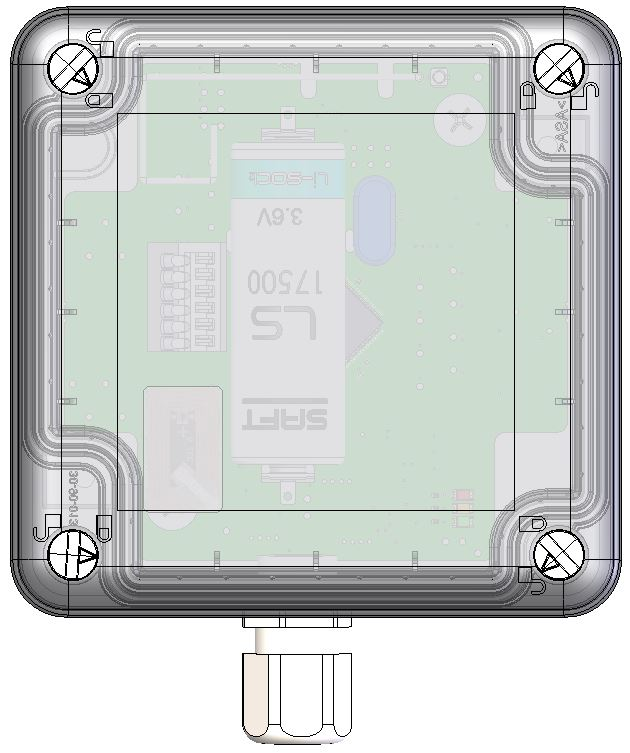

The PT1000 temperature sensor is a LoRaWAN class A sensor that manages an internal battery. It also incorporates an internal antenna.

The sensor doesn't include a PT1000 probe, but it is compatible with 2 or 3 wires PT1000 probes.

The device allows the measurement of temperature over a wide range of values. It can measure from -40°C to +240°C with a precision of 0.1°C due to internal electronic.

The housing is compatible with the following DIN rail adapter:

Family code:

The family code of Remote temperature devices is: 50-70-126.

LoRaWAN release

v1.0.2 Region Parameter rev B

Installation and operation

Installation

The product is delivered without probe. This enables the connection to the push-button terminals.

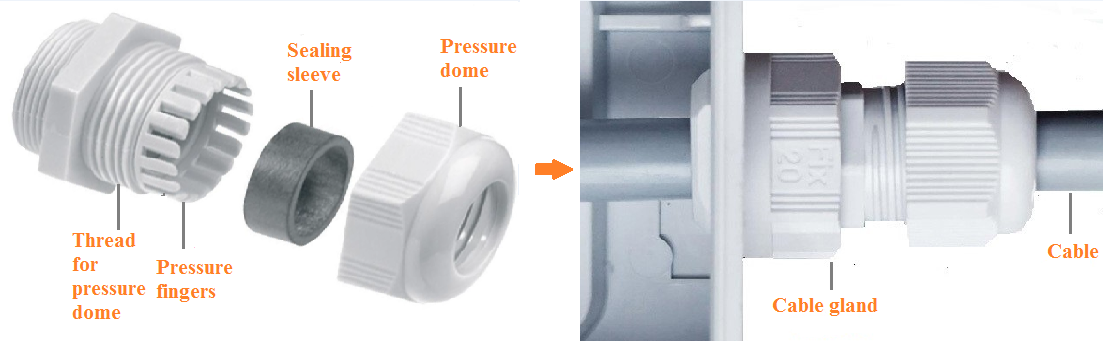

Before connecting your cable strands to the product’s terminals, you must insert the cable gland's nut and the seal.

Then connect the wires of the probe to the Inputs will be used:

- For 3 wires PT1000, connects as follow:

- For 2 wires PT1000, it is necessary to strap the two right terminal blocks together:

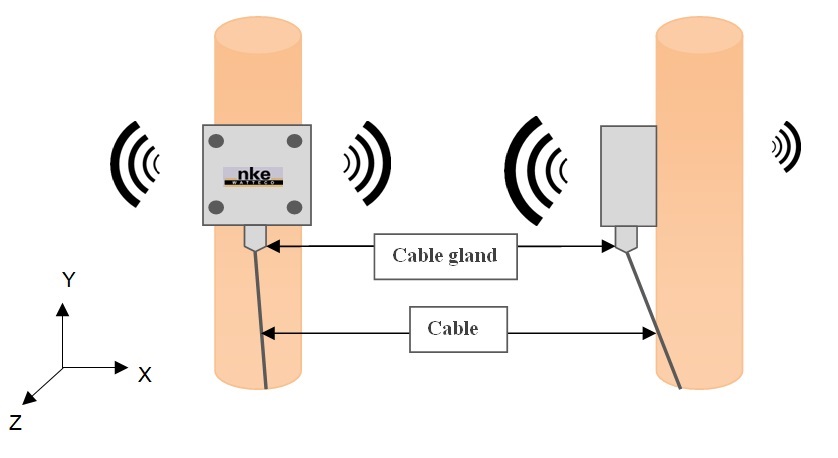

Radio propagation

In order for the sensor to operate correctly, the number of obstacles should be limited in order to avoid excessive radio wave attenuation. It is also important to place the sensor as high as possible. The cable gland should be positioned downward.

Autonomy

The information in the table below represents how long the battery can last. It is based on the default configuration at ambient temperature (+25°C) within the optimal operating range of the sensor via a LoRaWAN network (one uplink frame), when the spreading factor used is SF12.

The disposable battery has a 3.6Ah capacity, of which 85% is used.

| Transmission periodicity | Battery life |

|---|---|

| 1 frame/ 2 hours | 12 years |

Human Machine Interface

The device sensor has a buzzer that allows it to “communicate” with the user.

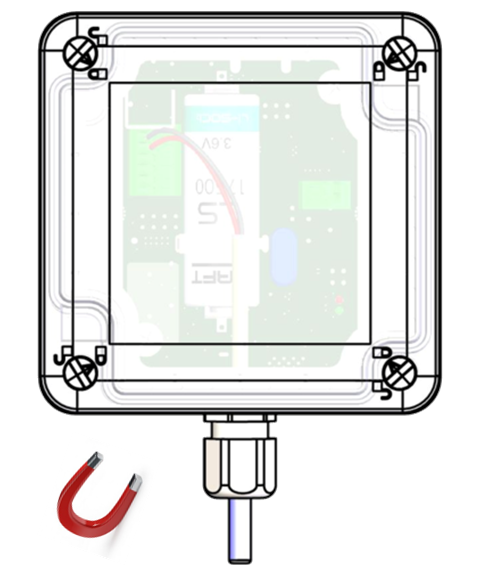

A reed switch is available under the "ILS" sticker. It is possible to use a magnet to activate it and makes specific actions on the sensor (Switch off, switch on, Re-associtation…). When the reed switch is activated, the buzzer rings quickly.

To Start-up the device, it is necessary to put a magnet on the side of the sensor during one second (at the left side of the cable gland). The buzzer rings quickly during this step. After this second, the buzzer stops and rings slowly until the association is done.

To switch off the device, use the same way by putting the magnet during 5 seconds. After this amount of time, the device rings 5 times slowly.

The table below describes the actions to be performed on the reed switch to disable or enable the storage mode.

| Switch ON (disable storage mode) | 1 second | |

| Switch OFF (enable storage mode) | 5 seconds |

When the sensor is trying to associate with a network, it emits the following sound:

Once the association is completed, the buzzer makes the following sound:

A reed switch (or magnetic switch) is available. A magnet can be used to activate it and perform specific actions on the sensor (switch off, switch on, reassociation…).

- Configuration: "void" frames are sent every minute for 10 minutes.

Standard reports are disabled in this mode.

| Way to trigger it | One passage of the magnet near the reed switch or specific ZCL command |

| Way to stop it | Another passage of the magnet or specific ZCL command |

| Effects on the sensor | |

| Duration | The configuration mode lasts 10 minutes |

- A reassociation procedure can be requested if no downlink frame is received by the sensor during a given periodicity (4 days by default) or if a given number (100 by default) is reached or in case of failure (no acknowledgement received) by sending an applicative frame to the sensor or via the sensor’s IHM.

The sensor keeps the AppEUi and DevAddr configured, Confirmed/Unconfirmed configuration and all applicative configurations. However, LoRaWAN configurations (channel, data rate…) are lost

| Way to trigger it | Three passages of the magnet near the reed switch or ZCL command from LoRaWAN cluster. |

| Effects on the sensor | |

- A factory reset is available on Watteco’s sensors. It deletes all the applicative settings saved in the flash memory (i.e. configured batches and reports will be deleted).

The sensor keeps the AppEUi and DevAddr configured. However, LoRaWAN configurations (channel, data rate…) and applicative configurations are lost.

| Way to trigger it | Two quick passages and a very long passage (until the sensor rings for the reset) of the magnet near the reed switch |

| Effects on the sensor | |

Applicative layer

Codecs are available to decode frames: Downloads

The PT1000 temperature sensor integrates the following clusters:

| Cluster | Cluster name | Managed attributes |

|---|---|---|

| 0x0000 | Basic | All |

| 0x0050 | Configuration | All |

| 0x8004 | LoRaWAN | All |

| 0x0402 | Temperature Measurement | All |

Default configuration

A default configuration is set:

- The device reports the temperature every 2 hours (EndPoint 0 / Cluster Temperature Measurement / Attribute Measuredvalue).

Every change made to the default configuration must comply with the legal duty cycle (for example, the most restrictive in the EU is 0.1%, which corresponds to approximately 1 frame per hour with SF12)

Measurement periodicity

The measurement periodicity depends on the minimum and maximum recording intervals, and the delta.

If the value of the minimum and the delta is 0, then the maximum value is the periodicity. However, if the value of delta is different than 0, then the periodicity is 1 second.

If the value of the minimum is different than 0, then this value is the same as the periodicity.

Frame examples

All frames have to be sent on port 125

Standard report

Report

Report of the temperature of the remote sensor→ Applicative payload is: 11 0a 04 02 00 00 29 00 64

00 64: Measured value 1°C (Temperature (°C) = Measured value/100)

Configuration

Configure a standard report on the temperatureReport immediately the temperature for every 11°C of variation. This measurement has to be reported at least every hour.

→The temperature is on the EndPoint 0, Cluster “Temperature Measurement” is 0x0402, Attribute “MeasuredValue” is 0x0000.

The maximum field has to be 0x0e10 to have a report every one hour and the minimum field has to be 0x0000 to have a report immediately after the right variation.

The delta has to be configured to 1100=0x044c for a report every 11°C of variation.

Applicative payload is: 11 06 04 02 00 00 00 29 00 1e 0e 10 04 4c

00 1e:minimum reporting interval (30 seconds)

0e 10: maximum reporting interval (1 hour)

04 4c: reportable change (11°C)

→Response: 11 07 04 02 00 00 00 00

To disable the previous configuration, change the value of the minimum and maximum sending intervals and the delta to 0: 11 06 04 02 00 00 00 29 00 00 00 00 00 00

Batch report

• Configure a batch report on Temperature and Battery voltage:

Timestamp and record the temperature with a resolution of 0.1°C, a value has to be saved at least every 6 hours or on a variation of 1°C.

Timestamp and record all power source voltages with a resolution of 0.1V, a value has to be saved at least every 24 hours. All data have to be concatenated and sent every 24 hours at the most.

→The solution to concatenate several different physical values in the same frame is to use batch reporting. For the batch, the number of physical measurements that will be sent must be known in order to choose a label for each of them and the size of these labels. There is only 1 power source in the sensor (disposable battery). So with the temperature and this power source, it is necessary to manage 2 different labels.

| Label number | Tag label | Tag size |

|---|---|---|

| 1 or 2 | 0/1 | 1 |

| 3 or 4 | 00/01/11/10 | 2 |

| 5 or 6 or 7 or 8 | 000/001/010/011/100/101/110/111 | 3 |

| ... | ... | ... |

The Tag Size to use for 2 labels is 1. Label 0 can be used for Temperature and Label 1 for level of Disposable Battery. To configure the batch, a command “Configure reporting” must be sent for each cluster.

For temperature, the delta has to be set to 100=0x0064 (1°C), minimum to 30=0x001e (30 seconds), the maximum to 6*60=360=0x8168 (6 hours), the resolution to 10=0x000A (0.1°C) and the tag to 0b00000001=0x01 (size 1 and label 0). The cluster to report is 0x0402 and the attribute 0x0000 (MeasuredValue).

For Disposable Battery power source the delta has to be set to 200=0x00c8 (0.2V), minimum to 10=0x800a (10 minutes), the maximum to 24*60=1440=0x85A0 (24 hours), the resolution to 200=0x0064 (0.1V), the tag to 0b00001001=0x0a (size 1 and label 1), the field to 4=0x04. The cluster to report is 0x0050 and the attribute 0x0006 (Node power descriptor).

| Power sources (Bits field) | Description |

|---|---|

| 0x01 | Constant (main) or External power |

| 0x02 | Rechargeable battery |

| 0x04 | Diposable battery |

| 0x08 | Solar harvesting |

| 0x10 | TIC harvesting |

| Others | Reserved |

| 0x00 | Undefined: should not occur |

11 06 04 02 15 00 00 00 00 1e 81 68 00 64 00 0A 01

15: 0b00010101 => 0001010: size of configuration string after attribute ID (10 bytes)

00 1e: minimum reporting interval (30 seconds)

81 68: maximum reporting interval (6 hours)

00 64: required delta value (size: 2 bytes for attribute MeasuredValue => attribute type = 29; 1°C)

00 0A: required resolution (0.1°C)

01: tag value (ob00000001 => 00000: tag label, 001: tag size)

→Response: 11 07 04 02 00 01 00 00

11 06 00 50 15 00 06 04 80 0a 85 a0 00 c8 00 64 09

15: 0b00010101 => 0001010: size of configuration string after attribute ID (10 bytes)

04: index of required field (Rechargeable battery)

80 0a: minimum reporting interval (10 minutes)

85 a0: maximum reporting interval (24 hours)

00 c8: required delta value (size: 2 bytes for attribute NodePowerDescriptor => attribute type = 41; 0.2V)

00 64: required resolution (0.1V)

09: tag value (ob00001001 => 00001: tag label, 001: tag size)

→Response: 11 07 00 50 00 01 00 06

To decode the batch reception, use br_uncompress. Type for Temperature is I16 (7) and for others the type is U16 (6), so the following command must be used:

echo "200200606025410d271ce80441ff9d230083ff6787f5b30f68b72cef9228" | br_uncompress -a 1 0,10,7 1,100,6

Result

DECOMPRESSION SERIES

cnt: 2 # Batch counter (from 0 to 7)

18450 # Timestamp in seconds of sending of the frame

# Format of data is: Timestamp of Measurement | Label | Value

811 0 2410 # Timestamp: 811 s Label 0: Temperature Value: 24,1°C

841 0 2550 # Timestamp: 841 s Label 0: Temperature Value: 25.5°C

911 0 -1250 # Timestamp: 911 s Label 0: Temperature Value:-12.5°C

941 0 -1370 # Timestamp: 941 s Label 0: Temperature Value:-13.7°C

12011 0 -1230 # Timestamp: 12011 s Label 0: Temperature Value:-12.3°C

844 1 3700 # Timestamp: 840 s Label 1: Disposable battery Value: 3.7V

1444 1 3500 # Timestamp: 840 s Label 1: Disposable battery Value: 3.5V