VAQA'O Lite series sensors

Presentation

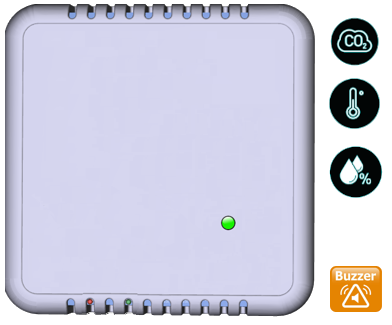

The VAQA'O Lt series devices are LoRaWAN Class A environmental sensors, powered by two 2600 mAh AA lithium batteries housed in internal slots.

The VAQA'O Lt can measure several environmental parameters, including temperature, humidity, carbon dioxide (CO2), and continuously monitor sensor movement.

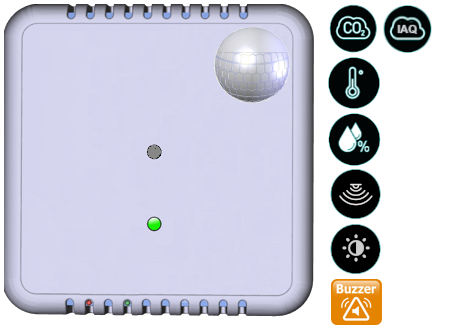

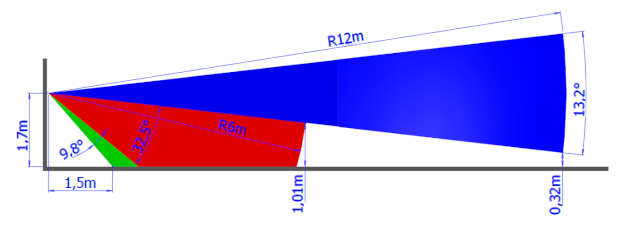

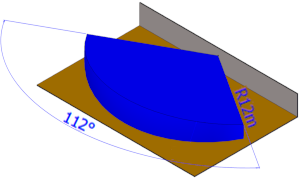

The VAQA'O+ Lt expands on this by adding room illuminance measurement and human presence detection, capable of detecting movement up to 12 meters away through an embedded passive infrared sensor.

The VAQA'O Multi Lt further enhances functionality with the addition of atmospheric pressure and volatile organic compound (VOC) measurement, utilizing an RMOX sensor.

Family code

|

|

| 50-70-223-xxx : VAQA'O Lt | 50-70-251-xxx : VAQA'O+Lt 50-70-217-xxx : VAQA'O Multi Lt |

For previous release of 50-70-074-xxx or 50-70-168-xxx , see older revision documentation.

Installation and operation

Installation

Manual and QuickStart guide are available in our download center.

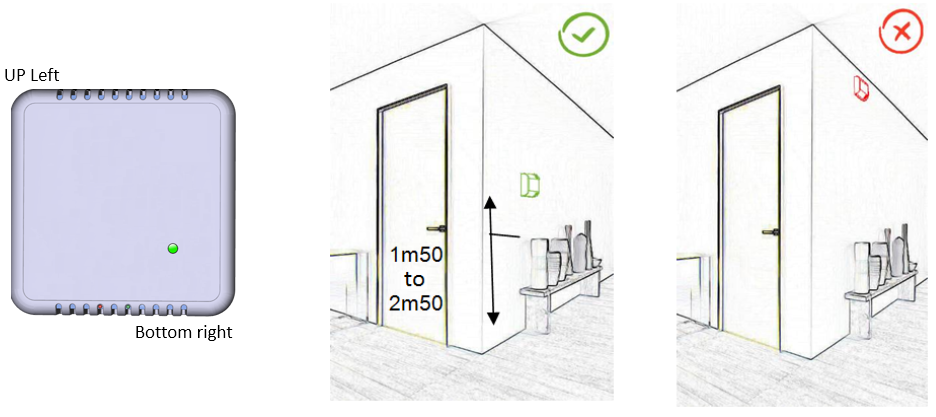

The housing should be installed inside a building, must be protected from any water spray and must be used in environnement with less than 80% relative humidity. The product should not be installed in direct heat source (Heater, sunlight, ...) to avoid local heating effects that may alter a global estimation of environmental parameters in the measured room. The product should be installed in a representative position in regard of the required environemental parameters survey. Usualy, it should be installed between 1m50 and 2m50 from floor.

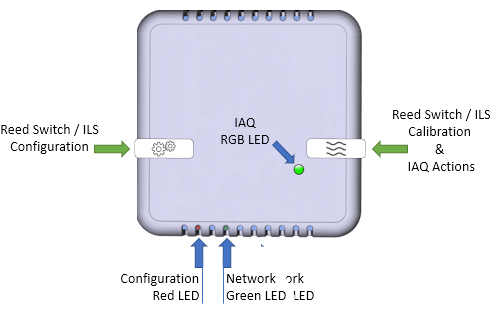

The product has 1 Green Led, 1 Red led, 1RGB led and two "magnetic switches" as human to machine interface. These elements should positioned as shown below when installing the sensor.

To correctly install the sensor:

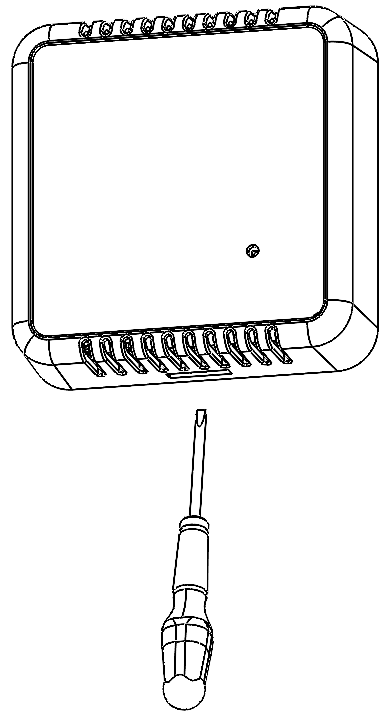

- Open the product from the two clips at the bottom using a small flat screwdriver.

- Use the base as a template and obtain horizontality using a level. Then hang the base on the wall using screws or double-sided tape. Thanks to the noticeably light weight of the product, you can use only two screws.

- Once done you can clip back the front, containing electronic parts, on the base.

- Please, DO NOT USE centered holes for the screws as their heads may interfere with the batteries!

|

|

|

Once installed, the two LEDs are visible through the bottom vertical windows and the magnetic switches can be actuated like simple buttons using a magnet.

|

|

|

It is important to start the device once fixed to the wall. The tilt box's pull-out alert function is based on the angle with the vertical. This initial angle is taken at startup, and a periodic check of the angle is performed. If the angle varies by more than 4 degrees from the initial position, then the alert is triggered. It is necessary to return to the initial angle ±2 degrees for the alert to be deactivated.

About CO2 and VOC/Indoor Air Quality index:

CO2 concentration is measured with a dedicated CO2 gaz sensor using NDIR technology. This measurement can be normative.

A separated MOX sensor embeded in VAQAO, is used to estimate an Indoor Air Quality Index. This AQI (or IAQ) is deduced from the measurement of the concentration of volatile organic compounds in the air. The compounds taken into account are numerous, such as formaldehydes, ethanol, acetone or others, coming from paints, cleaning products, solvents, alcohol, glues, etc and even CO2 itself. The concentration attribute for IAQ gives an estimator of air polution with the following scale:

Note about the "Indoor Air Quality" index: The device uses a "Static IAQ" index of the MOX sensor". This index is suitable for "non-mobile" use. The VOC sensor gradually adapts to its environment, and the value read is "normally" between 0 and 500. However, it can make excursions, greater than 500, in the event of "significant/sudden" variations in the environment. As an indication, the "IAQ" value (rather for mobile use) is really constrained between 0 and 500, by specific filtering. This value is available on Concentration cluster Endpoint 2, but it is not part of the default reporting configuration.

Following table summarize Classifications, default values and HMI display for CO2 and/or VOC.

| Level Value | level name | CO2 | VOC | IAQ Led blink |

| 0 | EXCELLENT | < 500 | 50 | GREEN (Default blinks each 30s) |

| 1 | GOOD | [500, 700] | [50, 100] | GREEN (Default blinks each 30s) |

| 2 | AVERAGE | [700, 1100] | [100, 150] | ORANGE (Default blinks each 15s) |

| 3 | BAD | [1100, 1300] | [150, 200] | ORANGE (Default blinks each 15s) |

| 4 | VERY BAD | [1300, 1700] | [200, 300] | RED (Default blinks each 7s) |

| 5 | UNHEALTHY | > 1700 | > 300 | RED (Default blinks each 7s) |

VAQAO+Lt / Multi Lt : PIR sensor detection area:

|

|

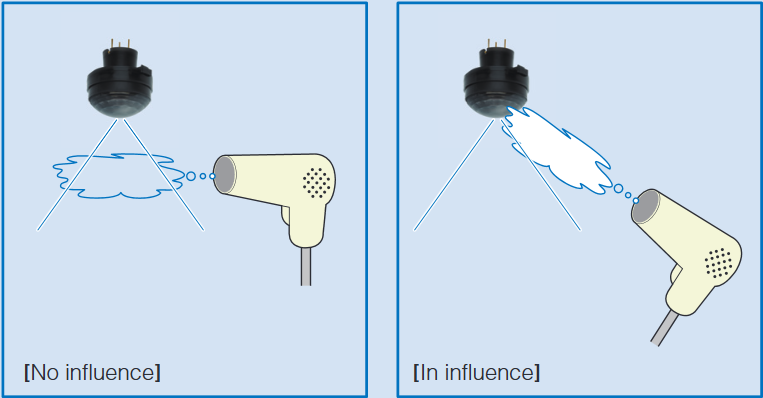

Warning: The PIR sensor should not be exposed directly to hot air flow (such as from a split air conditioning unit) as it may cause false detections.

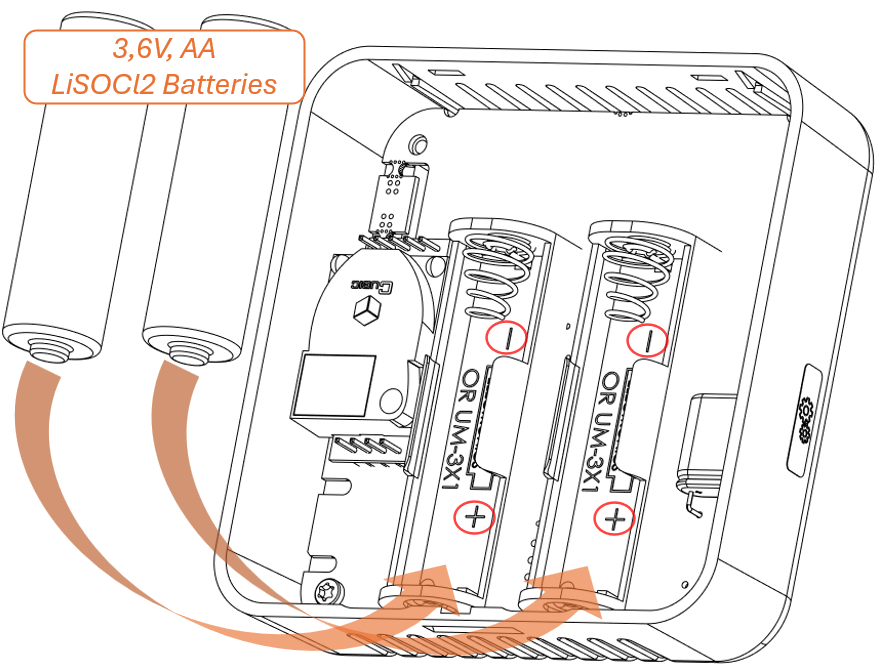

Replacing batteries

Batteries should be replaced with lithium-thionyl-chloride (Li-SOCI2) LR6/AA of 2600mAh each (example: SAFT LS14500). The batteries can be replaced on the fly, one after each other, as each battery slot is protected against side overvoltage.

However, operator must carefully avoid any short circuit or electrostatic discharge during battery replacement.

However, operator must carefully avoid any short circuit or electrostatic discharge during battery replacement.

Steps to replace batteries are:

- Open the product from the large center clip at the bottom using a small flat screwdriver.

- Use a plastic spludger to extract batteries from their slots and replace them with new ones.

BEWARE that batteries must all be placed in the same direction. Notice the "+" sign on the PCB.

Renew this operation for the 2 other batteries. - Once done you can clip back the front containing electronic parts, on the base starting from upper side.

Autonomy

The information in the table below represents how long the batteries can last. It is based on the default configuration at ambient temperature (+25°C) within the optimal operating range of the sensor via a LoRaWAN network (one uplink frame), when the spreading factor used is SF12.

Following estimations are given with default reporting configuration and using two 2.6Ah capacity 3,6v AA Li-Ion batteries installed, of which 85% is used.

With the default configuration the sensor will record all significative measurements up to once each 10 minutes and at least once per hour. Then batch reports will be regularly send containing all these last measurements. It may contain several sample for any of the measured parameters (T, H, CO2). Some specific reports/alarms may also be sent because of default configuration (case opening, threshold crossing for Temperature, Humidity, CO2, ...). Due to all these possibly reported information, consumption estimation is based on a periodic transmission in range from 20 minutes to one hour.

Battery life expectancy :

| Transmission periodicity | Spreading factor | VAQAO Lt VAQAO+Lt : 1 or 2 months less |

|---|---|---|

| 1 Frame / Hour | SF12 | 5 years |

| 3 Frames / Hour | SF12 | 3,5 Years |

| 1 Frame / Hour | SF9 | 7 Years |

| 3 Frames / Hour | SF9 | 6 Years |

Note: Activating Buzzer and TAP HMI can reduce the battery life expectancy by up to 1 year.

Human Machine Interface

3 LEDs are available on VAQA'O Lt. 2 LEDs Green and Red are visible through the down ears of the sensor. These are the usual leds of Watteco sensors giving indication about current "Network status and running modes". One more led (RGB) is available in the front of the sensor mainly used as a "CO2 level visual indicator" and can also be used during "Operator calibration actions" when "Calibration and IAQ button" on the right side of the sensor is used.

![]() Common configuration actions:

Common configuration actions:

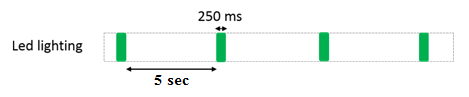

Network status and running modes HMI (Watteco sensors common behaviour) There are, 1 magnetic switch ("Gear ") and two LEDs to interact with the product: GREEN LED : LoRaNetwork status, mainly working when sensor try to join a network. Standard reports are disabled during this configuration mode. The sensor keeps the AppEUi and DevEUI configured, Confirmed/Unconfirmed configuration and all applicative configurations. However, LoRaWAN configurations (channel, data rate…) are lost. The sensor keeps the AppEUi and DevEUI configured. However, LoRaWAN configurations (channel, data rate…) and applicative configurations are lost.

RED LED : mirror for actuating the "magnetic switch" by flickering, and blinking during configuration mode.

Switch ON

(disable storage mode)1 second

Switch OFF

(enable storage mode)5 seconds

Consequently, "Void" frames are then sent every minute for 10 minutes allowing to probe uplink communication and send quickly downlink frames (configurations, requests, ...) to the class A sensor.

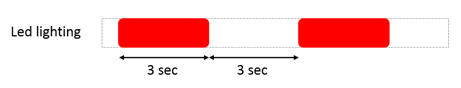

Way to trigger it One press on the USER button or specific ZCL command

Way to stop it Another press on the USER button or specific ZCL command

Effects on the sensor The CONF led (red) blinks (3 sec. OFF, 3 sec. ON) and the sensor sends an uplink frame every minute. The blinking is illustrated below this table.

Duration The configuration mode lasts 10 minutes when it is triggered by pressing the USER button

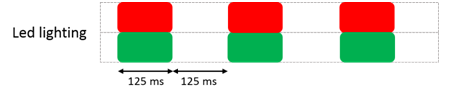

Way to trigger it Three short presses on the USER button or ZCL command from LoRaWAN cluster.

Effects on the sensor The ASSO LED (green) blinks as the “no commissioned sensor” LED is lit.

Way to trigger it Two short presses and one long press for approximately 7 seconds on the USER button.

Effects on the sensor The CONF LED (red) and ASSO LED (green) blink at the same time briefly. All the applicative settings (for batches and reports) are deleted. The blinking is illustrated below this table.

![]() IAQ actions:

IAQ actions:

Automatic CO2 Level indicator HMI Below the Default automatic display of current CO2 level. Notice that VAQA'O Lt gives the visual indication about co2 level on its "IAQ led" according to some tunable parameters like Period or Thresholds. Please refer to "Concentration levels classification attributes" to learn more about that function. User triggered CO2 Level indicator HMI User can require an immediate display of current CO2 level indication by one TAP or one magnet pass or on the right magnetic switch (IAQ) of the sensor. After that the current level will be displayed through 7 blinks with the current CO2 level indication. CO2 Calibration HMI and fresh air calibration selection The calibration can be managed through magnet HMI. During this process the user can, These functions can be actuated by starting the Calibration configuration process with 3 passes on the right (IAQ) (magnetic switch) with the Magnet. When started the IAQ Led indicator will chase across the 3 colors Orange, Green, Blue during 30s. From there the device is waiting for action selection. The following animation shows a case where the user, looks at current ABC state (First pass => gives Orange so ABC is OFF), then roll over possible actions, and finally actuate an immediate "fresh air calibration" (Green). Once any action is selected, this one will startup about 10s later without any new action (pass) from the user. And notice that any multiple quick passes with the magnet during this selection will interrupt current calibration process. CO2 Calibration HMI : Example of calibration running Below shows a "calibration process running". It can occur after having selected an "immediate fresh air calibration" or "when a periodic ABC is running ". It will then display successively following states: CoDecs are available to decode frames: Downloads All downlink frames have to be sent on port 125 Please, try and see also Watteco Online codecs The VAQA’O Lt device implements many applicative clusters associated to different sensors entries. The associations between measurement functionalities and EndPoints/Clusters are shown below: VAQA'OLt sensors implements a default Batch and Standard configuration that manages all embedded measurements through a periodic reporting of up to 2 frames per hour. This default configuration can be summarized as follow: It records environmental parameters with a 10 minutes max time sampling and sends them once or twice per hour: On VAQA'O Lt : In addition on VAQA'O+Lt : In addition on VAQA'O Multi Lt: It monitors critical events on environnemental parameters Any of these configurations can be removed or modified, and some different ones can be set. However, every change made to the default configuration must comply with the legal duty cycle. For example, the most restrictive in the EU is 0.1%, corresponds to approximately 2 frames per hour with the most constrained Spreading Factor : SF12. See also Detailed defaul configuration below or "Concentration cluster" Remenber that VAQAO is a ClassA sensor, so all downlinks will be delayed until the next Uplink delay. ABC calibration (Default 'Off') Set ABC calibration 'On': 31 05 800C 800A 20 01 Set ABC calibration 'Off': 31 05 800C 800A 20 00 Set ABC calibration period (Default 5) Set ABC calibration period to 10 days: 31 05 800C 800A 20 0A Start an immediate fresh air calibration The air around the sensor must be "fresh" since at least 30 minutes (openned windows, or after a day without anybody inside the room). 31 50 800C 03 Calibrate based on actual and expected value This calibration is quite fast (less than 1 minute after the DL is effectively sent), so it is not influenced by the current CO₂ concentration. Just ensure the air is stable during this operation. This calibration is typically used when the “floor” of your logged CO₂ values over a day or a week is significantly higher than 450 ppm, even though you know the air was fresh during that period. In this case, you tell the sensor that the actual minimum measured value 31 50 800C 02 XXXX 01C2 Buzzer alarms (Default 'Off') In fact this set the period of buzzing in seconds, when alarm is on. Setting it to 0 <0x0000>, removes the buzzing. Set Buzzer alarms 'On / 60s': 31 05 800C 8031 21 003C Set Buzzer alarms 'Off / 00s': 31 05 800C 8031 21 0000 TAP HMI (Default 'Off'. Beware, 'On' may reduce life expectancy of about 1 year) This command activate the ta sensing by activatinf accelerometer chock detection at 100Hz, threshold 256mg. Setting back parameter to 0x000 remove tap sensing. Tap HMI 'On': 11 05 000c 8004 19 9410 Tap HMI 'Off': 11 05 000c 8004 19 0000 Note that each frame is preceded by a one-byte size prefix. When used for downlink on port 125 within most LoRaWAN infrastructures, this size prefix should be removed. VAQA'O Lt / VAQA'O+Lt / VAQA'O Multi Lt # ------------------------------------------------------------------------------------------ VAQA'O Lt sensors has got an alternate default configuration that can be activated instead of default one. In this alternate configuration Batch is not used. Beware that this configuration is more verbose on radio and will drain battery faster. Following configuration commands can be used to swap between default configuration and alternate one: VAQA'O Lt / VAQA'O+Lt / VAQAO # All report unconfirmed Codecs are available to decode frames: Downloads Please, try and see also Watteco Online codecs Typical VAQA'O Lt batch report Input uplink frame to decode: 303480878e3001a70858829068d7846940ca02da798223d0ae09d36e5912c002 Batch attributes : 3 1,10,7,T 2,100,6,H 3,10,6,CO2 Decoding results: (Try it) { Report on violation (sensor moved from its original position) Input frame: 110a000f00551001 Decoded payload: (Try it) {"version": "Frame_Codec_v_1.0.svn5087", "TimeStamp": "2020-03-02 17:01:45.232452"} Alarm on Humidity level getting lower than specified threshold Input frame: 318a0405000021053398b0 Decoded payload: (Try it) {"version": "Frame_Codec_v_1.0.svn5087", "TimeStamp": "2020-03-02 16:58:38.024454"} Alarm on CO2 level getting lower than Thresold Input frame: 318a800c000021023a98b0 Decoded payload: (Try it) {"version": "Frame_Codec_v_1.0.svn5087", "TimeStamp": "2020-03-02 17:06:46.277547"}

Excellent to Good

(Period: 30s)

Average to Bad

(Period/2: 15s)

Very Bad to Unhealthy

(Period/4: 7s)

Triggered with Tap (if activated)

showing Good

Triggered with magnet

showing Average

Each action can now be successively required by one more short pass with the magnet. The first short pass will show the current ABC calibration state: Blue => ABC ON; Orange ABC OFF. The next short passes will turn around the four following states:

Applicative layer

Cluster Cluster name EndPoint: Rôle Product Managed attributes

0x0402 Temperature EP0 (0x11): Accuracy +/-0,5°C [1/100 °C] All All

EP1 (0x31): Accuracy +/-0,2°C [1/100 °C] All All

0x0405 Relative humidity EP0 (0x11): Accuracy +/-3% [1/100 %RH] All All

EP1 (0x31): Accuracy +/-2% [1/100 %RH] All All

0x800C Concentration EP0 (0x11): VOC [IAQ] Multi Lt All, Except calibration attributes and commands

EP1 (0x31): CO2 [ppm] All All

0x0400 Illuminance EP0 (0x11): Illuminance [Lux] + LtMulti Lt All

0x0406 Occupancy EP0 (0x11): Occupancy [1: Occupied, 0: Unoccupied] + LtMulti Lt All

0x000F Binary input EP0 (0x11): Effraction status [1: Yes, 0: No] All All

0x0403 Pressure (Ambiant atmospheric) EP0 (0x11): Ambiant atmospheric pressure [1/10 mBar or hPa] Multi Lt All

0x0000 Basic EP0 (0x11): Sensor firmware and hardware informations All All

0x0050 Configuration EP0 (0x11): Sensor global configuration parameters and commands All All

0x8004 LoRaWAN EP0 (0x11): Sensor LoRaWAN parameters management All All

Default "Main" configuration

The "Batch" part

The "Standard" part

Typical/Usual/Basic DL configurations

<0xXXXX> should be 450 ppm <0x01C2>.Detailed default configurations

Main configuration

# NOTICE: Following configurations are used for "Vaqao Lt", "Vaqao + Lt" and "Vaqao Multi Lt" default config

# Configuration frames for inexistant sensors "Lux", "Occupancy", "Pressure" or "VOC" clusters will simply be

# rejected when corresponding sensors are not available

#

# Beware that each configuration frame is prefixed by its one byte size.

#

# ---------CFG 0 (Default): CONF FOR BATCH & STANDARD REPORTS ------------------------------

# . All report unconfirmed

08 11 05 8004 0000 08 00

#

# . PIR config

# Occ to Unocc delai: 30min (30 minutes WITHOUT move (notice that PIR activity won't be processed 1/10 x 30mn )

09 11 05 0406 0010 21 0708

# UnOcc to Occ delai: 0s (Immediatly)

09 11 05 0406 0011 21 0000

#

# . CO2 Configuration

# Set Autocalibration period to 5 days and UNACTIVATED by default

08 31 05 800C 8009 20 05

# Since VAQAO V2. A bit can activate(01)/inactivate(00). [and (02) for only under min ABC (Do not use, test only)

# Used to activated or deactivated by downlink or HMI without loosing clibration period.

# Note: Autocalibration period must also be != 0, to validate activation

08 31 05 800C 800A 20 00

# Set normal min concentration value: 430ppm (0x01AE)

09 31 05 800C 8008 21 01AE

# Set number of oversampling points to 5 (Mainly for CM1106NS sensor) (Effective used number is coerced in 1 to 32)

08 31 05 800C 8011 20 05

#

# . IHM LED ON CO2 :

#09 11 05 800C 8020 21 FFFF

09 31 05 800C 8020 21 001E

#

# . IHM BUZZER ON CO2 :

# CO2 default unactivated : Alarm period=0xFFFF; Alarm pause period = (24 * 60) mn; Thresh High/Low UNHEALTHY/VERY_BAD

09 31 05 800C 8031 21 FFFF

09 31 05 800C 8032 21 05A0

08 31 05 800C 8033 20 05

08 31 05 800C 8034 20 04

#

# LIS2DE TAP detection (Think about devopt LIS2DE et TAP bit activation (cf InfoMem.7010xxxVyy))

# Note about TAP configuration examples:

# 0x0000 : (b00 0000 00 / 0 0000000) No chock/click measurement for default conf hence no Click management.

09 11 05 000c 8004 19 0000

# 0x9410 : (b10 0101 00 / 0 0010000) Click/100Hz/2g/(16*16)=256mg

# 0x5503 : (b01 0101 01 / 0 0000011) Chock/100Hz/4g/(3*32)=96mg

# 0x5D03 : (b01 0111 10 / 0 0000011) Chock/400Hz/8g/(3*62)=186mg

# 0x5703 : (b01 0101 11 / 0 0000011) Chock/100Hz/16g/(3*186)=558mg

# 09 11 05 000c 8004 19 9410

#

# . Delete all report configurations (Batch and Standard)

06 11 50 0050 02 03

#

# ----------------------- CONFIGURE ACTIONS -------------------------

#

# ACTION 0: Starts CO2 Fresh air calibration

# Used for "Under Normal min" calibration by action on threshold.(See below)

0D 11 05 0050 FF00 41 05 31 50 800C 03

#

# ------------------------ STANDARD REPORTS -------------------------

# . OCCUPANCY (EKMB110411) [Occupancy state 0/1]

# . ROOM occupation changes

# Min 1s => 0x0001, Max max, Delta=1

# Note: Min 1minute, but beware that "UnOcc to OCC" and "Occ to UnOcc" params at the begining ("PIR config")

# impact also the reporting behaviour.

0D 11 06 0406 00 0000 18 0001 FFFF 01

#

# . POWERDESC [mV]

# . Periodic MAX = 5 J => 7200mn => x9C20; MIN = 10mn => 0x800A

# . Length of remaining payload (for 0x41 type ): 0x08

# . ALARM on power treshold : 2,9v (hyst 100mV)

# RP : NewCfg/Reserved/ShortCause/SecuredIfAlarm/AllNotSecured/HeaderKept/NotBatch : b 1 0 01 1 0 0 0 ==> x98

# CSD : IsAlarm/OnExceed/OnFall/Threshold/Slot0 : b 1 1 1 10 000 ==> xF0

# Disposable battery field index : 0x04

# THRS: 2900 : 0x0B54; HYST: 100 mV : 0x0064

# OCC : 2

14 11 06 0050 98 0006 41 800A 9C20 07 F0 04 0B54 0064 02

#

# . VIOLATION (Effraction based on sensor displacement) ([Binary state 0/1]

# . Configured with soft binary management based on angle 0: < 4° / 1: > 6° (hardcoded)

# . Angle measurement period: 60s (harcoded if no confg on angle_measurement)

# . Binary config: EDGE_BOTH (3)

# . Box openning and closing report

# Min 1s => 0x0001, Max max, Delta=1

0D 11 06 000F 00 0055 10 0001 FFFF 01

#

# . CO2 CONCENTRATION [ppm]

# STANDARD REPORT:

# . Periodic MAX = Inf => xFFFF; MIN = 10mn => 0x800A

# . ALARM on treshold HIGH: 1500; hyst 100

# RP : NewCfg/Reserved/ShortCause/SecuredIfAlarm/AllNotSecured/HeaderKept/NotBatch : b 1 0 01 1 0 0 0 ==> x98

# CSD : IsAlarm/OnExceed/OnFall/Threshold/Slot0 : b 1 1 1 10 000 ==> xF0

# THRS: 1500 : 0x05DC; HYST: 100 : 0x0064

# OCC : 2

12 31 06 800C 98 0000 21 800A FFFF F0 05DC 0064 02

#

# Force a fresh air calibration if concentration is "Under Normal min" concentration value

# . Periodic MAX = Inf => xFFFF; MIN = 10mn => 0x800A

# . ALARM on treshold LOW:

# Fresh air band is : 430 +/-65 (based on error specification/and experiment of sensor: 40 + (5*430/100))

# Try to go back to correct fresh air if : reading is < 430 - 65, ie: 365 => Set a threshold at 360 +/- 5

# RP : NewCfg/Reserved/ShortCause/SecuredIfAlarm/AllNotSecured/HeaderKept/NotBatch : b 1 0 01 1 0 0 0 ==> x98

# CSD : IsAlarm/OnExceed/OnFall/ThresholdWithAction/Slot1 : b 1 0 1 11 001 ==> xB9

# THRS: 360 : 0x0168; HYST: 5 : 0x0005

# OCC : 2

# ACTION: (Without report b1 / taille 2 b000 0010) (82) / Fresh air calibration (0000)

15 31 06 800C 98 0000 21 800A FFFF B9 0168 0005 02 82 0000

#

# Report CALIBRATION STATUS, on calibration ended

# . Periodic MAX = Inf => xFFFF; MIN = 10s => 0x000A

# . DELTA on treshold LOW: 430; hyst 50

# RP : NewCfg/Reserved/ShortCause/SecuredIfAlarm/AllNotSecured/HeaderKept/NotBatch : b 1 0 01 1 0 0 0 ==> x98

# CSD : IsAlarm/OnExceed/NotOnFall/Delta/Slot0 : b 1 1 0 01 000 ==> 0xC8

# DELTA : EndClockS field (1) changed : 0x00000001

# OCC : 1

13 31 06 800C 98 8000 41 000A FFFF 06 C8 01 00000001

#

# . VOC LEVEL (bme680) ** SIAQ ** [0-500]

# . Periodic MAX = Inf => xFFFF; MIN = 10mn => 0x800A

# . ALARM on treshold HIGH: 300; hyst 50

# RP : NewCfg/Reserved/ShortCause/SecuredIfAlarm/AllNotSecured/HeaderKept/NotBatch : b 1 0 01 1 0 0 0 ==> x98

# CSD : IsAlarm/OnExceed/OnFall/Threshold/Slot0 : b 1 1 1 10 000 ==> xF0

# THRS: 300 : 0x012C; HYST: 50 : 0x0032

# OCC : 2

12 11 06 800C 98 0000 21 800A FFFF F0 012C 0032 02

#

# . Température [°c/100]:

# . Periodic MAX = Inf => xFFFF; MIN = 10mn => 0x800A

# . ALARMS on Thresholds High and Low:

# RP : NewCfg/Reserved/ShortCause/SecuredIfAlarm/AllNotSecured/HeaderKept/NotBatch : b 1 0 01 1 0 0 0 ==> x98

# Thresold LOW: 14°C (0x0578); Hyst : 0.2°C (0x0014)

# CSD : IsAlarm/OnExceed/OnFall/Threshold/Slot0 : b 1 1 1 10 000 ==> 0xF0

# OCC : 1

# Thresold HIGH: 28°C (0x0AF0); Hyst : 0.2°C (0x0014)

# CSD : IsAlarm/OnExceed/OnFall/Threshold/Slot1 : b 1 1 1 10 001 ==> 0xF1

# OCC : 1

18 31 06 0402 98 0000 29 800A FFFF F0 0578 0014 01 F1 0AF0 0014 01

#

# . Humidity [%/100]:

# . Periodic MAX = Inf => xFFFF; MIN = 10mn => 0x800A

# . ALARMS on Thresholds High and Low:

# RP : NewCfg/Reserved/ShortCause/SecuredIfAlarm/AllNotSecured/HeaderKept/NotBatch : b 1 0 01 1 0 0 0 ==> x98

# Thresold LOW: 35% (0x0DAC); Hyst : 1% (0x0064)

# CSD : IsAlarm/OnExceed/OnFall/Threshold/Slot0 : b 1 1 1 10 000 ==> 0xF0

# OCC : 1

# Thresold HIGH: 65% (0x1964); Hyst : 1% (0x0064)

# CSD : IsAlarm/OnExceed/OnFall/Threshold/Slot1 : b 1 1 1 10 001 ==> 0xF1

# OCC : 1

18 31 06 0405 98 0000 21 800A FFFF F0 0DAC 0064 01 F1 1964 0064 01

#

# ------------------------- BATCH REPORT ---------------------------------------

# . OCCUPANCY

# Min 1s => 0x0001, Max 1h, Delta=1, resol=1, Tag Label 0, Tag Size 3, Type Bool 1

0F 11 06 0406 11 0000 00 0001 803C 01 01 03

# . TEMPERATURE (SHTC3)

# Min 10mn => 0x800A, Max 1h, Delta=0.1degC, resol=0.1degC, Tag Label 1, Tag Size 3, Type I16 7

11 31 06 0402 15 0000 00 800A 803C 000A 000A 0B

# . HYGROMETRY (SHTC3)

# Min 10mn => 0x800A, Max 1h, Delta=1%, resol=1%, Tag Label 2, Tag Size 3, Type U16 6

11 31 06 0405 15 0000 00 800A 803C 0064 0064 13

# . CO2 CONCENTRATION (CM1106NS)

# Min 10mn => 0x800A, Max 1h, Delta=10ppm,resol=10, Tag Label 3, Tag Size 3, Type U16 6

11 31 06 800C 15 0000 00 800A 803C 000A 000A 1B

# . VOC LEVEL (BME680) ** SIAQ **

# Min 10mn => 0x800A, Max 1h, Delta=10, resol=10, Tag Label 4, Tag Size 3, Type U16 6

11 11 06 800C 15 0000 00 800A 803C 000A 000A 23

# . ILLUMINANCE

# Min 10mn => 0x800A, Max 1h, Delta=10, resol=10, Tag Label 5, Tag Size 3, Type U16 6

11 11 06 0400 15 0000 00 800A 803C 000A 000A 2B

# . PRESSURE (BME680)

# Min 10mn => 0x800A, Max 1h, Delta=10, resol=10, Tag Label 6, Tag Size 3, Type U16 6

11 11 06 0403 15 0000 00 800A 803C 000A 000A 33

#

# Typical batch decoding parameters:

# ----------------------------------

# Batch frame examples (hexadecimal):

# - Vaqao Lt: 303480878e3001a70858829068d7846940ca02da798223d0ae09d36e5912c002

# - Vaqao + Lt: <Todo>

# - Vaqao Multi Lt: 70060000e2760090cfc0015b028423fb03272919804c121c003ebc5bd6895f0040000b68b72c27a0ddb4dc8076db920c68b72c19605b04

# Watteco Online batch decoder parameters for Vaqao Lt or Vaqao + Lt or Vaqao Multi Lt:

# 3 0,1,4,OCC 1,10,7,T 2,100,6,H 3,10,6,CO2 4,10,6,COV 5,10,6,LUX 6,10,6,P

#---------------------------------------------------------------------------------------------Alternate 'No Batch' configuration

08 11 05 8004 0000 08 00

#

# Remove current reports configuration (Standard and batchs)

06 11 50 0050 02 03

#

# T: 30mn or variation of 0.4degC, no more than once per minute

0F 31 06 0402 80 0000 29 8001 801E 48 0028

#

# RH: 30mn or variation of 4%, no more than once per minute

0F 31 06 0405 80 0000 21 8001 801E 48 0190

#

# VBATT: 24 h ou or variation of 0.5V, no more than once per minute

12 11 06 0050 00 0006 41 800a 85a0 05 00 04 01f4 00

#

# VIOLATION: 24 h or changing, no more than once per minute

0D 11 06 000f 00 0055 10 8001 85a0 01

#

# CO2: Periodic report + calibration under normal min level

# 1h ou ar variation of100ppm, no more than once per 10 minutes secured to avoid missed data

0F 31 06 800c 84 0000 21 800a 803c 48 0064

# Force a fresh air calibration if concentration is under Normal min concentration value (see parameters in default CFG 0)

15 31 06 800C 98 0000 21 800A FFFF B9 0168 0005 02 82 0000

# Report CALIBRATION STATUS, on calibration ended (see parameters in default CFG 0)

13 31 06 800C 98 8000 41 000A FFFF 06 C8 01 00000001

#

# COV(IAQ 0-500): 1h or variation of 100, no more than once per 10 minutes

0F 11 06 800c 84 0000 21 800a 803c 48 0064

#

# Atmos. pressure: 60 mn or variation of0,5mBar(<=>5m), no more than once per minute

0F 11 06 0403 80 0000 29 8001 803c 48 0005

#

# PRESENCE:

# Occ to Unocc after30m without move

09 11 05 0406 0010 21 0708

# UnOcc to Occ delai: 0s (Immediatly)

09 11 05 0406 0011 21 0000

# Report 12h or changing, no more than once per 10 minutes

0D 11 06 0406 00 0000 18 800a 82d0 01

#

# LUMINOSITY:12h or 50lux variation, no more than once per minute

0E 11 06 0400 00 0000 21 8001 82D0 0032Received frame examples

Batch report

"batch_counter": 4,

"batch_relative_timestamp": 993649,

"batch_absolute_timestamp": "2022-11-02T14:36:00.535",

"dataset": [

{

"data_relative_timestamp": 990648,

"data": {

"value": 2370,

"label": 1,

"label_name": "T"

},

"data_absolute_timestamp": "2022-11-02T13:45:59.535Z"

},

{

"data_relative_timestamp": 993048,

"data": {

"value": 2360.0,

"label": 1,

"label_name": "T"

},

"data_absolute_timestamp": "2022-11-02T14:25:59.535Z"

},

{

"data_relative_timestamp": 993648,

"data": {

"value": 2350.0,

"label": 1,

"label_name": "T"

},

"data_absolute_timestamp": "2022-11-02T14:35:59.535Z"

},

{

"data_relative_timestamp": 993048,

"data": {

"value": 6800,

"label": 2,

"label_name": "H"

},

"data_absolute_timestamp": "2022-11-02T14:25:59.535Z"

},

{

"data_relative_timestamp": 990561,

"data": {

"value": 590,

"label": 3,

"label_name": "CO2"

},

"data_absolute_timestamp": "2022-11-02T13:44:32.535Z"

},

{

"data_relative_timestamp": 992361,

"data": {

"value": 610.0,

"label": 3,

"label_name": "CO2"

},

"data_absolute_timestamp": "2022-11-02T14:14:32.535Z"

}

]

}Standard report

{

"EndPoint": 0,

"Report": "Standard",

"CommandID": "ReportAttributes",

"ClusterID": "BinaryInput",

"AttributeID": "PresentValue",

"AttributeType": "Boolean",

"Data": true,

"Cause": []

}

{

"EndPoint": 1,

"Report": "Standard",

"CommandID": "ReportAttributesAlarm",

"ClusterID": "RelativeHumidity",

"AttributeID": "MeasuredValue",

"AttributeType": "UInt16",

"Data": 1331,

"Cause": [

{

"ReportParameters": {

"New": "Yes",

"Reserved": 0,

"CauseRequest": "Short",

"SecuredIfAlarm": "Yes",

"Secured": "No",

"NoHeaderPort": "No",

"Batch": "No"

},

"SlotDescriptors": [

{

"CriteriaSlotDescriptor": {

"Alarm": "Yes",

"OnExceed": "No",

"OnFall": "Yes",

"Mode": "Threshold",

"CriterionIndex": 0

}

}

]

}

]

}

{

"EndPoint": 1,

"Report": "Standard",

"CommandID": "ReportAttributesAlarm",

"ClusterID": "Concentration",

"AttributeID": "MeasuredValue",

"AttributeType": "UInt16",

"Data": 570,

"Cause": [

{

"ReportParameters": {

"New": "Yes",

"Reserved": 0,

"CauseRequest": "Short",

"SecuredIfAlarm": "Yes",

"Secured": "No",

"NoHeaderPort": "No",

"Batch": "No"

},

"SlotDescriptors": [

{

"CriteriaSlotDescriptor": {

"Alarm": "Yes",

"OnExceed": "No",

"OnFall": "Yes",

"Mode": "Threshold",

"CriterionIndex": 0

}

}

]

}

]

}